We introduced a PVC outer cover in our yurts that last 10+ years, replacing the canvas covers that need to be changed every 2-3 years. As a synthetic material, PVC covers are great for protecting the yurt from UV light and other elements. However, they are not breathable, and issues of condensation, mold, and mildew need to be dealt with. None of the modern yurt makers that use PVC covers have solved these issues; many people using modern yurts struggle with these issues without clear instructions provided by the makers.

In this post, we explain how we addressed the challenge of letting the moisture out in our yurts.

Traditional Mongolian yurts use all-natural materials because synthetic materials were not available back then. Even until the early 1900s, Mongolian yurts had only sheep wool felts as the only cover (see this video). Traditional yurts started to get water-resistant canvas and cotton outer covers only in the 1970s as these materials became available in Mongolia.

These natural materials work okay in a relatively dry Mongolian climate, but not without problems. The cotton outer cover must be replaced every 3-5 years because it gets dirty and tears easily. The water-resistant canvas has limits; water penetrates it if it rains for a few days. But the natural materials have a great advantage – breathability. Moisture is created inside the yurt from various sources; from cooking to breathing. The key insulator in Mongolian yurts, the felt layer, absorbs the moisture, and when the yurt is heated from inside, the moisture evaporates out of the yurt. The water-resistant layer and cotton canvas layers let the moisture out through them.

When natural materials are used outside of Mongolia in humid climates, their disadvantages are exacerbated. First of all, cotton and canvas covers get dirty very easily and tear down from UV light in just 1-2 years. Below is a photo of a yurt sold by another Mongolian yurt seller who brags about selling breathable yurts. The owner of the yurt, who is selling it, wrote that this yurt was used only for a year.

The cotton outer cover looks nice when they are new; many people get fooled by the new look. But it will get dirty after a few months. The cover can be cleaned with a pressure washer to be used for another year, but nothing will prevent them from tearing down from UV light in 2-3 years like the one below supplied by the same company.

One of the most common inquiries we get is for replacement outer cover for yurts made by other companies. It is not difficult to replace these materials in Mongolia because they are readily available and affordable. But it is difficult to replace them when the yurt is outside of Mongolia; there is a whole set of challenges, including challenges with tailoring the cover for a good fit, high transportation costs, and having to replace it again in a few years after paying hundreds, if not thousands of dollars just for the cover.

In the winter, snow needs to be removed from the yurt roof because the thin ice layer from melting snow can block the airflow and remove the breathability advantage.

For these reasons, we shifted to a PVC cover, which can easily last up to 30 years, is easy to clean, and keeps a good look. But it is not breathable!

The issue of condensation and moisture mold is very real for users of modern yurts, which are made of wood frames, radiant insulation, and PVC covers. Nothing is in between the plastic cover and the people inside the modern yurts. People are inside a vacuum covered by plastic material, where air can escape only through the small cracks in the dome and windows. These are often not enough for air circulation, and there are so many complaints about humidity, condensation, water dripping and mold on online forums and social groups for yurt living.

So, what is our solution?

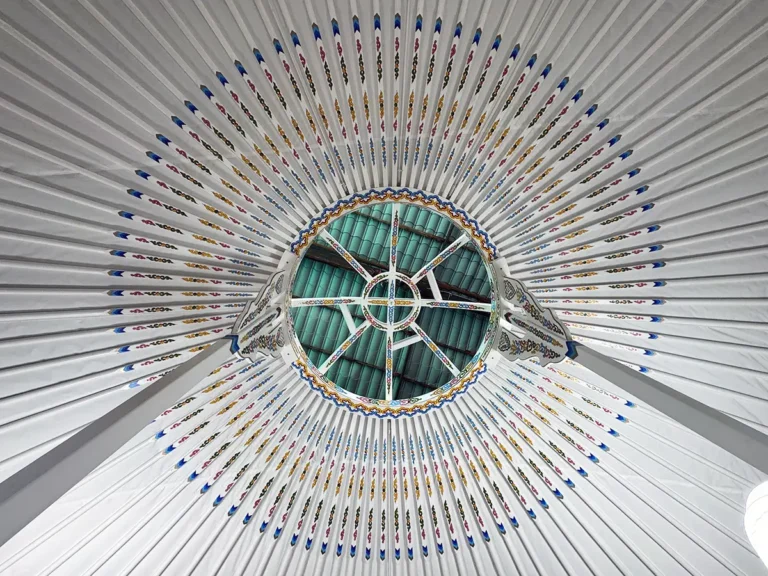

First of all, our yurts have five layers of materials between the wood frame and PVC cover. These include (1) cotton inner cover; (2) moisture barrier, a one-way breathable material that prevents the moisture from transferring to the felt; (3) thick wool felt; (4) vapor layer; (5) reflective layer. Therefore, there is no feeling of being inside of big plastic vacuum. People inside the yurt feel and smell natural materials of cotton and felt.

Next, we introduced the vapor layer, number (4) above, which creates a 1cm gap between the felt and the reflective layer, through which any moisture accumulated in the felt can escape. Below is a photo of a yurt being test assembled where the vapor layer is put on the felt. The finished yurt would have the reflective layer and the PVC layer on the vapor layer.

The vapor layer is a fire-resistant material that has recently been used under sidings and roofs for ventilation in modern buildings. It is a new material, and only a few innovative builders have been using it recently.

When the yurt is heated from inside by a heat source or outside by the sun, the moisture in the felt leaves with the air, following the route of least resistance. The vapor layer creates just that space, and the result has been great. It is a very useful addition to our yurts, which are already full of great features available nowhere else.